Material selection of concrete piston

2019-04-08

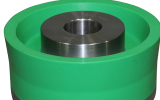

Concrete piston is one of the main stress parts and vulnerable parts of concrete pump and pump truck. It is installed in the concrete cylinder and connected with cooling water tank to push concrete when working. Therefore, it requires high wear resistance and sufficient strength when pumping under high pressure. At the same time, a certain degree of corrosion resistance is required. At present, butadiene-eye rubber and polyurethane rubber are widely used in domestic concrete piston.

Due to more and more high-rise pumping in China and the irregular gradation of concrete, the outlet pressure of concrete pump must be increased. The maximum outlet pressure has reached 21 MPa, while the strength of butadiene-eye rubber piston can not meet the requirements of high-pressure pumping. Therefore, polyurethane concrete piston has become the mainstream. However, the life of polyurethane concrete piston is usually 6000-11000 m3, and the quality of polyurethane concrete piston is unstable in use. Fixed, short life. The performance characteristics are: the life of concrete piston is discrete, and the early failure of some pistons in high temperature weather.

The piston polyurethane of concrete pump in piston type concrete pump is the main key part. Its durability and other quality problems are related to the working condition of piston. Therefore, it is very important to choose a durable and good quality piston. The piston polyurethane of concrete pump has good wear resistance, high strength, strong supporting force and high bearing pressure.

Polyurethane, full-name polyurethane rubber, has good wear resistance, high strength, good elasticity and other excellent physical and mechanical properties. Polyurethane is divided into polyester type and polyether type, which have different characteristics. Polyester polyurethane rubber has the characteristics of high strength, weather resistance, oil resistance and heat resistance. It can work for a long time in the air of 130 to 100 degrees Celsius or vegetable oil below 90 degrees Celsius, but its water resistance, strong acid resistance and alkali resistance generate more heat in use. Polyether polyurethane rubber has the characteristics of general polyurethane rubber. In addition to its general properties, it also has good hydrolysis resistance, mildew resistance and low temperature resistance. There are two kinds of polyurethane piston on the market: polyester piston and polyether piston. The two materials have their own characteristics. In order to satisfy high pressure pumping, polyester polyurethane rubber is usually used for high strength, but considering water resistance, strong acid resistance and strong alkali resistance, polyether polyurethane rubber is also needed.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码