Types and Characteristics of Sealing Devices for Hydraulic Seals

2019-03-29

Key words: Hydraulic seals; Seals; Characteristics

1. Clearance seal: Clearance seal relies on the small clearance between the matching surfaces of relative moving parts to seal. It is often used in the cylindrical matching pairs of plungers, pistons or valves. Generally, there are several equal-distance pressure equalizing grooves on the outer surface of the valve core. Its main function is to make the radial pressure distribution uniform, reduce the hydraulic clamping force, and make the valve core medium in the hole, so as to reduce the clearance. The advantage of the method to reduce leakage is small friction, but the disadvantage is that it can not be automatically compensated after wear. It is mainly used between cylinders with smaller diameter, such as between plunger and cylinder in hydraulic pump, and between spool and hole of slide valve.

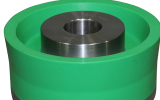

(piston seal)

2. O-ring: O-ring is generally made of oil-resistant rubber, its cross-section is round, it has good sealing performance, inside and outside sides and end face can play a sealing role, compact structure, small friction resistance of moving parts, easy manufacturing, easy assembly and disassembly, low cost, and high and low pressure can be used, so it is widely used in hydraulic system.

(O-type sealing-polyurethane cylinder)

In addition to rectangular grooves, there are also V-shaped, swallow-tailed, semi-circular, triangular grooves for the installation of O-ring seals. The relevant manuals and national standards can be consulted in practical application.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码