Properties of Polyurethane Elastomers Part II

2019-01-07

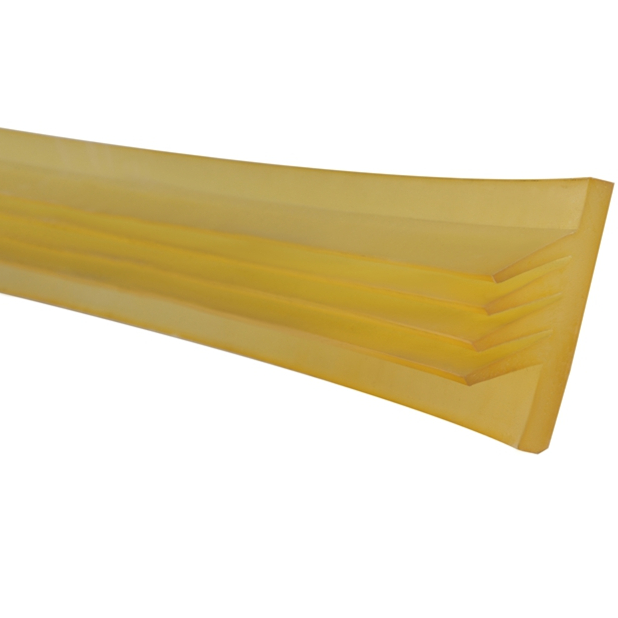

7. Hardness

The hardness of ordinary rubber ranges from Shao A20 to Shao A90. The hardness of plastics ranges from Shao A95 to Shao D100. The hardness of polyurethane elastomer ranges from Shao A10 to Shao D80, and it does not need the help of fillers. Especially valuable is that elastomer still has good elasticity and elongation under plastic hardness, while ordinary rubber can obtain higher hardness only by adding a large number of fillers and at the cost of greatly reducing elasticity and elongation. It is reported that when the hardness is higher than 75D, the elasticity will be seriously damaged. When the hardness is higher than 85D, the elastic material will be inelastic.

8. Tensile Strength

Polyurethane elastomer has high tensile strength, which is manifested in Young's modulus, tear strength and bearing capacity.

Young's modulus and tensile strength

Within the elastic limit, the ratio of tensile stress to deformation is called Young's modulus (E) or becomes elastic modulus. Like other elastomers, polyurethane elastomers obey Hooke's theorem only at low elongation (about 2.5%). But its Young's modulus is much higher than other elastomers. Moreover, the Young's modulus range of polyurethane elastomers is wider than that of rubber and plastics, which is incomparable with other materials.

tear strength

The tear strength of polyurethane elastomer is very high, especially polyester type, which is more than twice that of natural rubber.

carrying capacity

Although the compressive strength of polyurethane elastomers is not high at low hardness, polyurethane elastomers can improve the hardness while maintaining the elasticity of rubber, thus achieving high load-carrying capacity. However, the hardness of other rubber is limited, so the load-carrying capacity can not be greatly improved.

9. Electrical Performance

The electrical insulation performance of polyurethane elastomer is better at general working temperature, which is roughly equivalent to the level of chloroprene rubber and phenolic resin. Because it can be cast and thermoplastic, it is often used as filling materials for electrical components and cable sheaths. Polyurethane elastomer has high molecular polarity and water affinity, so its electrical properties vary greatly with ambient temperature, and it is not suitable for high frequency electrical materials. In addition, the electrical properties of polyurethane elastomers decrease with the increase of temperature and increase with the increase of hardness.

10. Radiation resistance

In synthetic macromolecule materials, polyurethane elastomer has good resistance to high-energy radiation. Satisfactory performance can still be obtained under the radiation dose of 105-106 Gy. However, for light-colored or transparent elastomers, discoloration occurs under the action of radiation, similar to that observed in hot air or atmospheric aging tests.

11. Mildew Resistance

Polyether polyurethane has good fungus resistance, the test grade is 0-1, that is, no fungus. However, polyester polyurethane is not mildew-resistant. The test results show that polyester polyurethane is mildew-prone. It is not suitable for field use in tropical and subtropical areas and storage in hot and humid conditions. Polyester-based Polyurethane Elastomers Used in the field and in hot and humid environments should be formulated with antifungal agents (such as octahydroxyquinoline copper, BCM, etc.). The general dosage is (0.1% - 0.5%) to improve their fungal resistance.

12. Biomedical

Polyurethane materials have excellent biocompatibility. Acute and chronic toxicological tests and animal experiments have proved that medical polyurethane materials have no distortion effect, no allergic reaction, no local irritation and no heat source. It is one of the most valuable synthetic medical polymer materials.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码