The Tensile Strength of Date Fiber/Polycaprolactone Biocomposites Developed by UK has been further enhanced

2018-12-26

Net News: A research team led by the University of Portsmouth in the UK has developed a new kind of bio-composite material, which uses date fiber to produce some non-structural components, such as car bumpers and door linings. The team also includes INRA from the University of Cambridge, the University of South Brittany and the French Institute of Agricultural Sciences.

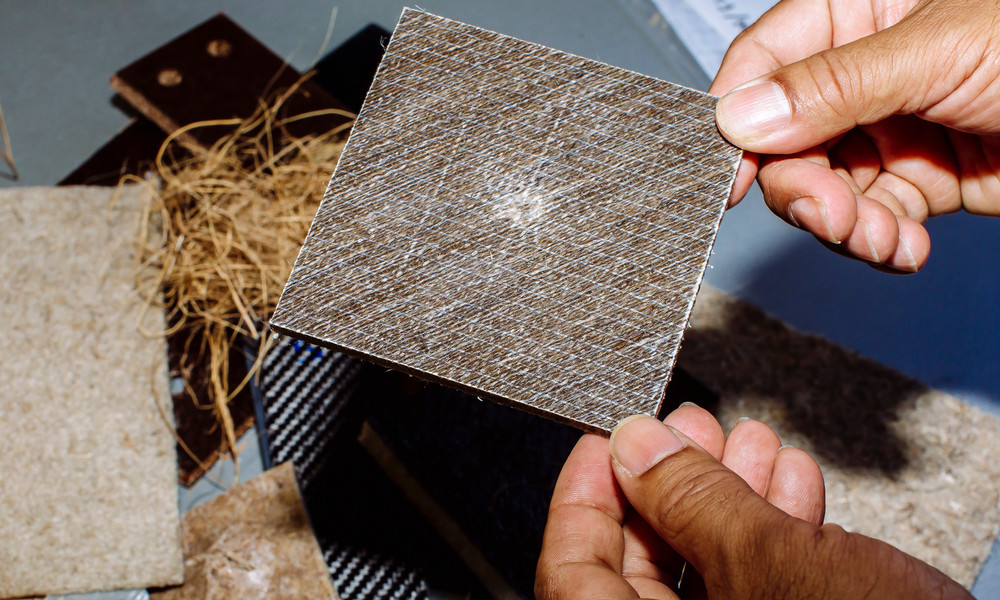

This kind of bio-composite material is made of date fiber and polycaprolactone (PCL), which is degradable, recyclable and renewable. It is a completely different bio-composite material from glass fiber composite material and carbon fiber composite material.

In a research report published in the Development Table, the team said that after mechanical properties testing, the tensile strength and low-speed impact resistance of jujube fiber/polycaprolactone composites were improved compared with traditional composites.

Dr. Hom Dhakal, head of the Advanced Materials and Manufacturing Research Group (AMM) at the University of Portsmouth and co-author of the report, said: "The use of date fiber reinforced materials opens up new ideas for the development of low-cost, sustainable and lightweight biocomposites."

"The results of this research will have a tremendous impact on the industry. It can not only be used as a lightweight substitute material to help automobiles achieve weight reduction and energy saving and emission reduction, but also consume less energy than glass fiber composite materials and carbon fiber composite materials. More importantly, it can be completely biodegradable and recycled.

It is also the first time that the mechanical properties of jujube fiber/polycaprolactone biocomposites have been fully evaluated.

It is understood that date fiber is the most common natural fiber in North Africa and the Middle East. The cultivation of jujube trees will produce a large amount of agricultural waste, which will cause serious environmental pollution and destroy the soil microbial system by burning or landfilling.

Dr. Dhakal added: "The research process is very long, and only enough calmness and perseverance can we achieve the desired results. One of the challenges we face is to ensure the stability and consistency of product performance. The other is to persuade customers to adopt this new and unfamiliar bio-composite material and use it to produce non-structural and structural components. In order to meet these challenges, we need the cooperation of industry and university, and further research and innovation.

Dr. Dhakal and his team have been working closely with the industry to test the strength of components made from natural fibers such as dates, flax, hemp and jute.

Disclaimer: The news content you see on Winsin Material Network comes from the network, does not constitute advertisements or is not used for commercial propaganda. It only transmits more information for free to the vast number of users. It does not mean that we agree with its point of view. There is no guarantee or commitment to the authenticity, completeness and timeliness of this article and all or part of its content and text. Readers are invited to refer to this website only. Please verify the relevant content by yourself. If you have doubts about the content, please contact us in time.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码