Application of Polyurethane Elastomer in Ceramic Mould

2018-12-24

Key words: ceramic mould; polyurethane elastomer; polyurethane prepolymer; ceramic mould

With the rapid growth of the production of building ceramics, the ceramic mould industry of wall tiles and floor tiles is facing more and more fierce challenges. Nowadays, the mould production is no longer satisfied with the general conventional manufacturing, but the best choice of the mould material for the die structure. At the same time, it also reduces and eliminates the defects of brick billet, so as to realize the high life, high quality and high efficiency of the whole set of moulds.

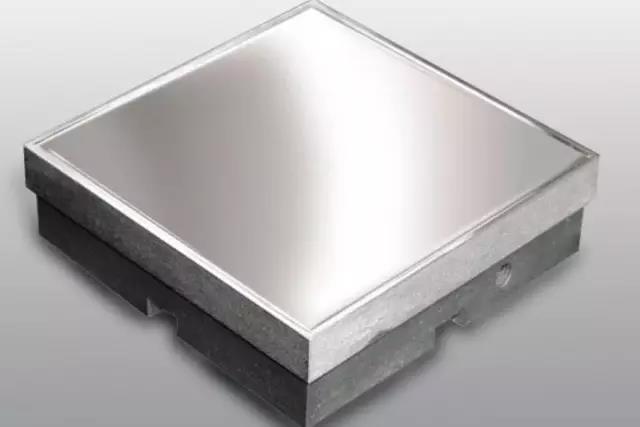

Brick press

In recent years, according to the situation of mould production, polyurethane rubber mould has been developed with domestic equipment and materials. Welcomed by users, the quality has reached the level of imported rubber moulds.

Polyurethane rubber mold, also known as rubber mold, is a kind of mold which covers a layer of polymer material with special properties on the surface of metal steel mold. It has been used abroad since 1980s. Although it started late in China, the development and manufacture of rubber mold and its wide application in ceramics industry have reached an advanced level in the world.

Performance characteristics of rubber moulds:

According to the analysis of working condition of general ceramic mould, it is required that the mould can bear the alternation of vertical impact force and horizontal push force at a certain temperature and humidity. The mould surface needs good resilience, non-sticking mud powder, high strength and good wear resistance. After hundreds of thousands of times of impact, no cracks and degumming occur in the adhesive layer, so as to ensure the size of the brick is accurate, the shape is regular, and the special features. Especially for the high-life edge die, not only the cutting edge needs excellent wear resistance, high surface finish, but also to ensure that the service life of the steel die is matched with more than 800,000 times. For isostatic pressing die, the requirement of glue surface is more stringent. In addition to satisfying the above conditions, the surface of the die should be deformed greatly under a certain pressure, so that the pressure can be transferred and the effect of isostatic pressing can be better.

Ceramic mold

Properties and characteristics of polyurethane elastomers:

Polyurethane rubber, also known as polyurethane elastomer, is widely used in stamping technology because of its high resilience, high wear resistance and excellent physical and mechanical properties. Its main advantages are:

With excellent wear resistance and wide hardness, elastomers with hardness from Shao A10 to Shao D80 can be obtained by selecting raw materials and adjusting formula.

It has good physical and mechanical properties and can work under 100MPa-1000MPa and ultra-high pressure, showing good tensile strength, tear strength and compressive strength.

Good elasticity. Permanent deformation is small.

Polyurethane rubber is known as "Liuxiu steel" because it has the properties of fluid flow in all directions, non-dispersive and strong enough like steel body. After repeated research and experiments, we confirmed that this "fluid steel" is used in surface modification of dies. It fully meets the requirements of ceramic mould performance.

Polyurethane prepolymer (polyurethane elastomer; ceramic mould adhesive)

Through years of technical accumulation in polyurethane industry, Winsin Materials Co., Ltd. has successfully replaced foreign brands in ceramic mould industry and broken the technological monopoly of foreign enterprises. The supply of a series of polyurethane prepolymers for the manufacture of core rubber layers can meet the various requirements that may be encountered in the application. With the common die core of our company's products, it can withstand more than 300,000 stamping times. We have an 80% share of China's domestic market.

The polyurethane layer on the core largely determines the performance of the core. The Alfonso pouring polyurethane prepolymer system of Yuanxing Material Company can effectively prevent texture deformation, dimension deformation, corner collapse and other problems that may occur in the process of ceramic tile pressing, and effectively prolong the life of the core.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码