Low Temperature Turning Polyurethane Cylinder Material--Aviation Hydraulic Seal

2018-12-17

Key words: low temperature resistant polyurethane cylinder material; polyurethane elastomer; low temperature resistant polyurethane

Material: Polyurethane

Function: oil seal

Scope of application: pumps, cylinders

Properties: corrosion resistance, high temperature resistance, high pressure resistance, wear resistance

Low Temperature Resistant Polyurethane Cylinder Material (LT-PU)

Physical Properties of Low Temperature Resistant Polyurethane

Low temperature resistant polyurethane cylinder material is a kind of casting polyurethane elastomer material. It not only provides better processing convenience, but also has the characteristics of low temperature resistance, cold resistance and low endogenous heat. After many practical occasions, it has been proved that this material can withstand the severe cold of -55 (℃) It has obvious advantages in applications with dynamic performance requirements. Various products manufactured with it have good performance in resilience, low temperature characteristics and oil resistance. All kinds of sealing elements manufactured with it are widely used in machinery, hydraulic pressure, locomotive parts and so on.

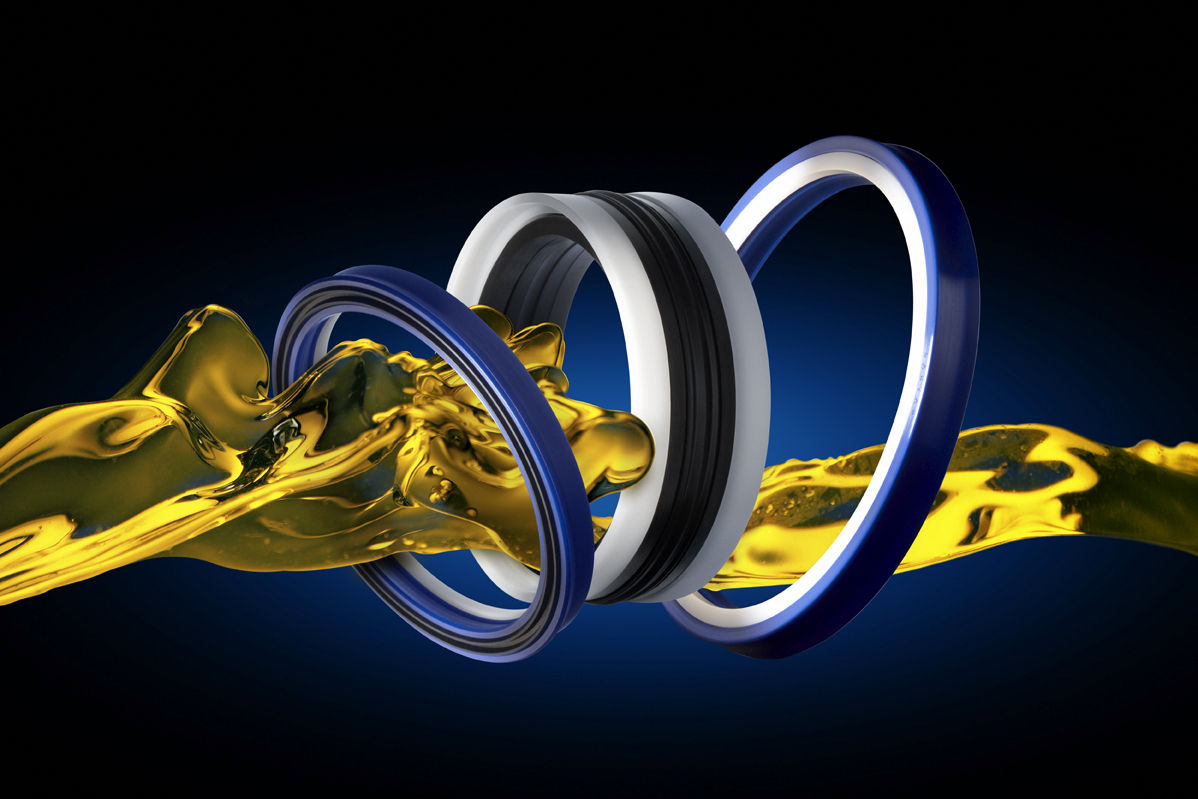

Diagram of Polyurethane Sealing Materials in Hydraulic Components

Low temperature resistant polyurethane (LT-PU) is suitable for use in places with low working temperature. The chemical properties of LT-PU are similar to those of HMP, but the lowest working temperature of LT-PU is extended to -50 C. For this reason, LT-PU has excellent performance in harsh climatic conditions and is suitable for the sealing of aviation hydraulic fittings and refrigerants.

Sealing design should first select appropriate sealing materials. The selection of sealing materials should take into account the temperature requirements of the selected materials and the chemical compatibility of sealing media, the movement speed of dynamic seals and the aging of sealing materials. Nowadays, aircraft design engineers are facing more and more severe temperature and chemical environment. A large number of Aeronautical elastic materials are used in aeronautical seals. Sealing rings can be manufactured by manual welding, automatic die casting, plant strengthening, or directly integrated into the metal parts.

Polyurethane Seal Display Chart

Winsin Materials Co., Ltd. is a leading developer and manufacturer of polyurethane prepolymer and polyurethane elastomer products in China. It is a high-tech enterprise in Guangdong Province and a member of China Polyurethane Industry Association. With our professional and technical accumulation and rich experience in the industry for nearly 20 years, we can provide you with high quality products, complete solutions and perfect technical services in product design, testing, manufacturing and use.

As the main material of modern sealing, polyurethane plays a key role in the whole sealing industry. Winsin Material has been devoted to the development and practice of polyurethane material application for a long time. With 20 years of polyurethane industry experience, the polyurethane barrel material provided by Yuanxing Material stands out with its super high cost performance ratio.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码