Polyurethane Resin as Catalyst for Ceramic Production

2018-12-10

Key words: ceramic mould; polyurethane; polyurethane elastomer

It has been thousands of years since human beings used ceramic tile as wall and bottom. With the continuous progress of modern industrial technology and the continuous improvement of people's requirements for ceramic tile, ceramic factories manufactured by traditional methods have been unable to meet the new needs.

Since the 1950s, with the vigorous development of chemical technology, in order to meet the efficiency and continuity of ceramic production and reduce production costs, a large number of elastomeric materials have been widely used in ceramic mould core making. After decades of demonstration, polyurethane stands out from all materials.

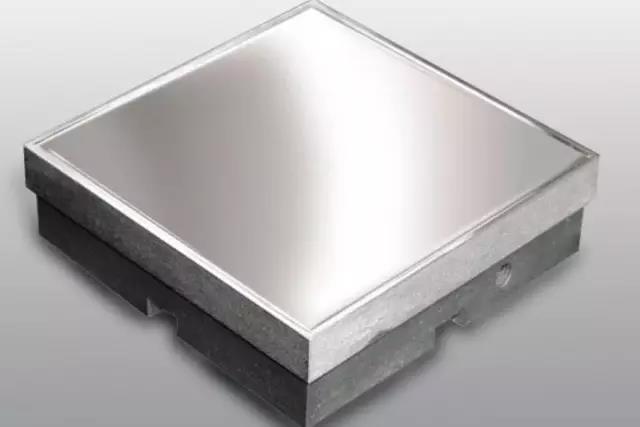

The die core for ceramic tile production is a composite structure of a layer of polyurethane elastomer adhering to the wear-resistant metal matrix. Compared with the integral metal core, the compound die core greatly simplifies the process of mould making and improves the processing efficiency of the die mass production by 3-14 times. At the same time, only one layer of polyurethane elastomer is needed for the maintenance of the die, which not only reduces the maintenance cost, but also improves the overall service life of the die.

Polyurethane rubber, also known as polyurethane elastomer, has high elasticity, high wear resistance and excellent physical and mechanical properties. It is widely used in stamping technology. Its main advantages;

With excellent wear resistance and wide hardness, elastomers with hardness from Shao A10 to Shao D80 can be obtained by selecting raw materials and adjusting formula.

It has good physical and mechanical properties and can work under 100 MPa to 1000 MPa high and ultra high pressures, showing good tensile strength, tear strength and compressive strength.

Good elasticity. Permanent deformation is small.

Polyurethane rubber is known as "Liuxiu steel" because it has the properties of fluid flow in all directions, non-dispersive and sufficiently strong like steel body. After repeated research and experiments, we confirmed that this "fluid steel" is used in surface modification of dies. Fully meet the production performance requirements of ceramic mould.

In the 1990s, the domestic ceramic industry began to develop vigorously. From the beginning, the whole core was imported to the die material imported to the final realization of nationalization, Winsin material is one of the most important parts - polyurethane material. The quality and life of the polyurethane layer on the core largely determine the performance of the core. Selection of appropriate adhesive layer material can effectively prevent the problems such as texture deformation, size deformation, corner collapse and so on that may occur in the process of ceramic tile pressing, and effectively prolong the life of the core.

We supply a series of polyurethane materials for the manufacture of core coatings, which can meet the various requirements that may be encountered in applications. With the common die core of our company's products, it can withstand more than 300,000 stamping times.

At present, we are proud of our 80% market share in domestic ceramic tile die industry. In the future, we will continue to forge ahead and achieve breakthroughs in service quality and product quality.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码