Winsin materials& BLASCH Composite Cyclone Separation Device has been successfully developed!

2018-11-26

Winsin Material is a hydrocyclone for separation and liquid classification applications, which is made of ceramic and polyurethane composites developed jointly with BLASCH Company. It has been put into use in the United States.

Technical characteristics of polyurethane hydrocyclone:

Simple structure, low cost, easy to install and operate; small size, small area, large processing capacity, low operating costs; simple processing technology, long-term stable operation after the operation parameters are determined, wide use, good wear resistance, long service life, high sorting accuracy, high efficiency.

Industrial applications of polyurethane hydrocyclones:

It is used in the classification process of petroleum industry, metal concentrator and non-metal concentrator, and in the desliming and dewatering of slurry material.

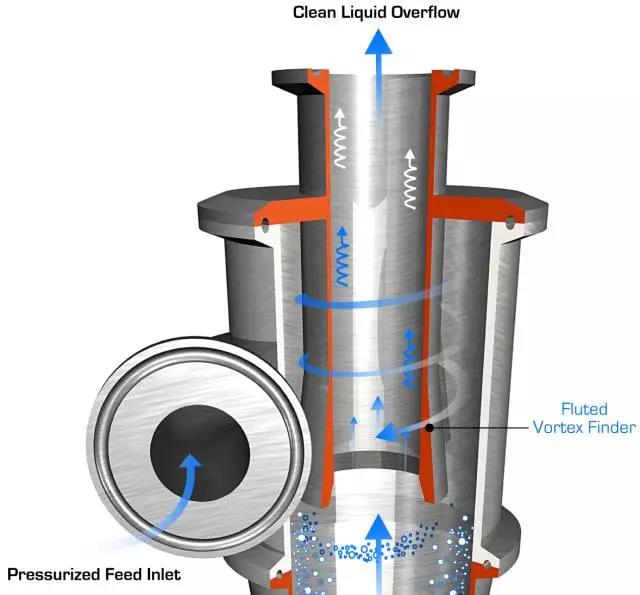

The working principle of polyurethane hydrocyclone:

When the two-phase (or three-phase) mixture to be separated enters the hydrocyclone tangentially from the periphery of the hydrocyclone at a certain pressure, a strong three-dimensional elliptical strong rotational shear turbulence is generated. Because of the difference in particle size (or density) between coarse particles (or heavy phase) and fine particles (or light phase), the size of coarse particles (or heavy phase) is different from that of fine particles (or light phase), such as centrifugal force, centripetal buoyancy, fluid drag force and so on. Under centrifugal sedimentation, most coarse particles (or heavy phase) are discharged through cyclone sediment outlet, while most fine particles (or light substances) are discharged through cyclone sediment outlet. Quality) is discharged by overflow pipe, so as to achieve the purpose of separation and classification.

Through the combination of polyurethane and high wear-resistant ceramics, we successfully combine the flexibility of polyurethane with the high wear resistance, high temperature resistance and corrosion resistance of ceramics, so that the life of cyclone can be greatly improved. At the same time, using its advantages, the installation cost of products made of traditional epoxy resin and polyurethane can be reduced.

With the materials provided by Winsin and Blasch casting process, features such as bows and complex mating joints can be put into the ends of these bushes to provide tight seals and reduce the wear opportunities associated with joint transition. At the same time, it can provide cushions of different thickness for users to choose.

A large number of test data show that the service life of the cyclone manufactured by this process and material can be increased by 2-10 times compared with the traditional products, and the cost of use can be greatly reduced.

Friendship Links:Winsin World Factory Network Shop

Copyright@ WINSIN MATERIALS,INC. 粤ICP备18139308号

简体中文

简体中文 EN

EN 二维码

二维码